Multi-Scale Topology Optimization of Discrete Lattice Structures

1.583 Final Project

Amira Abdel-Rahman

PhD Student

Center for Bits and Atoms (CBA)

Background

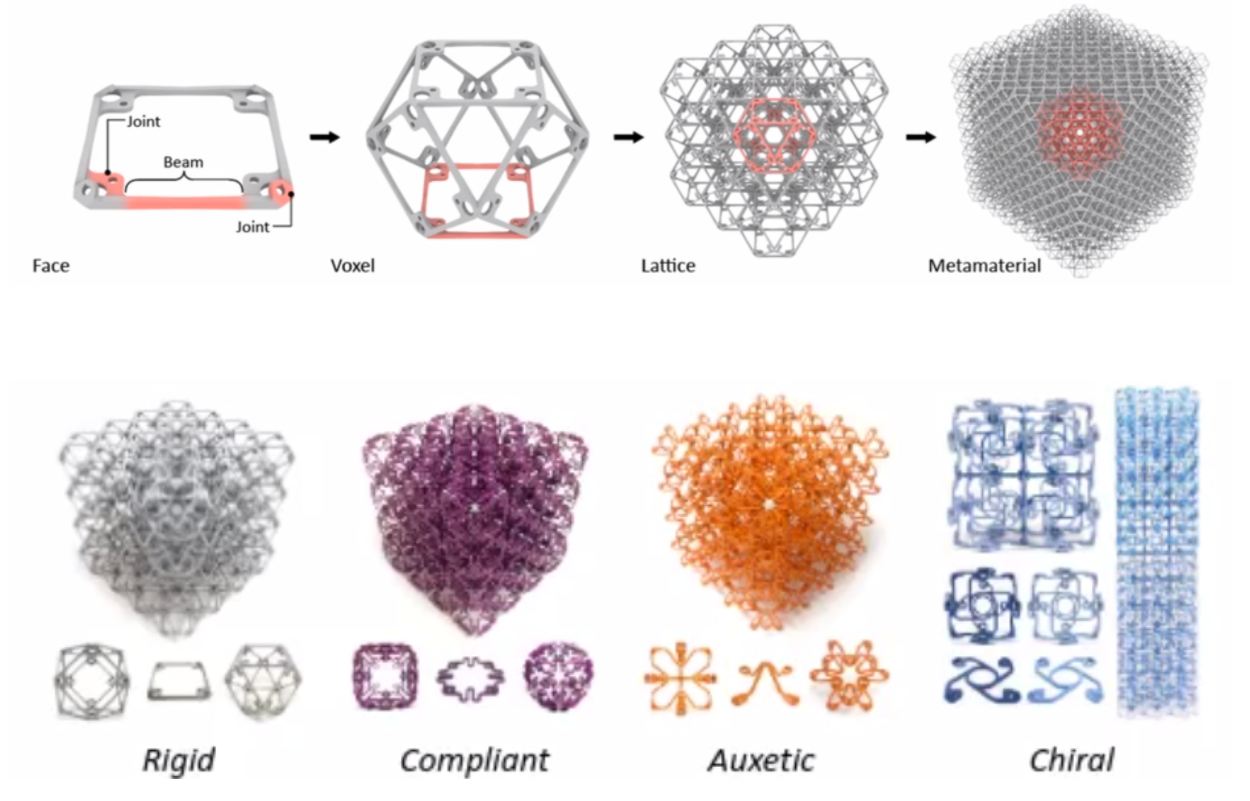

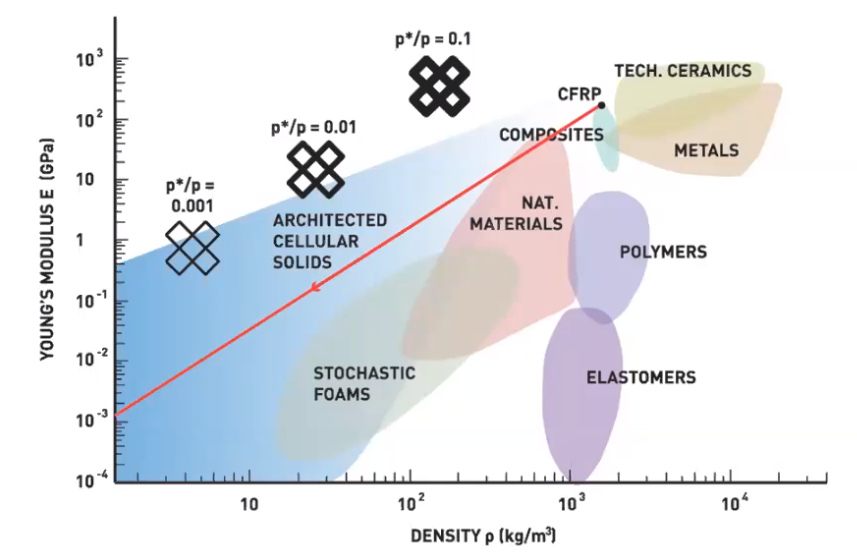

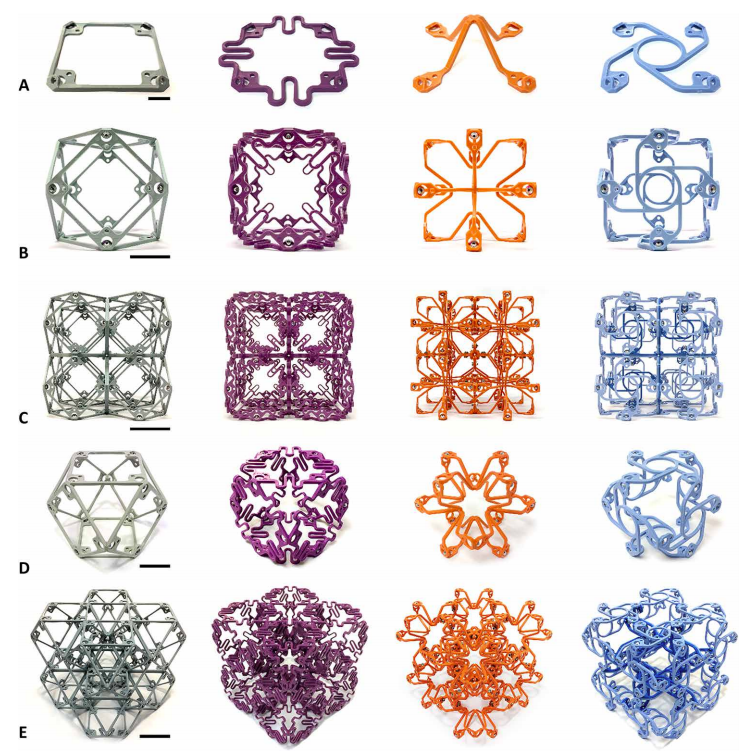

Digital Material

Discrete set of parts with relative positions and orientations; where global geometry is determined from local constraints, reversibly join parts with dissimilar properties to build heterogeneous functional systems.

* Benjamin Jenett, Christopher Cameron, Filippos Tourlomousis, Alfonso Parra Rubio,Megan Ochalek, and Neil Gershenfeld. Discretely assembled mechanical metamaterials.Science Advances, 6(47):eabc9943, 2020.

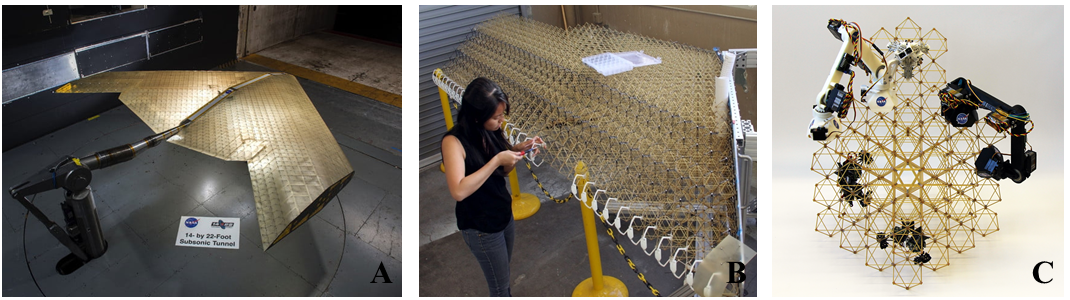

Applications

Test Case Study: Morphing Wing

Project Overview

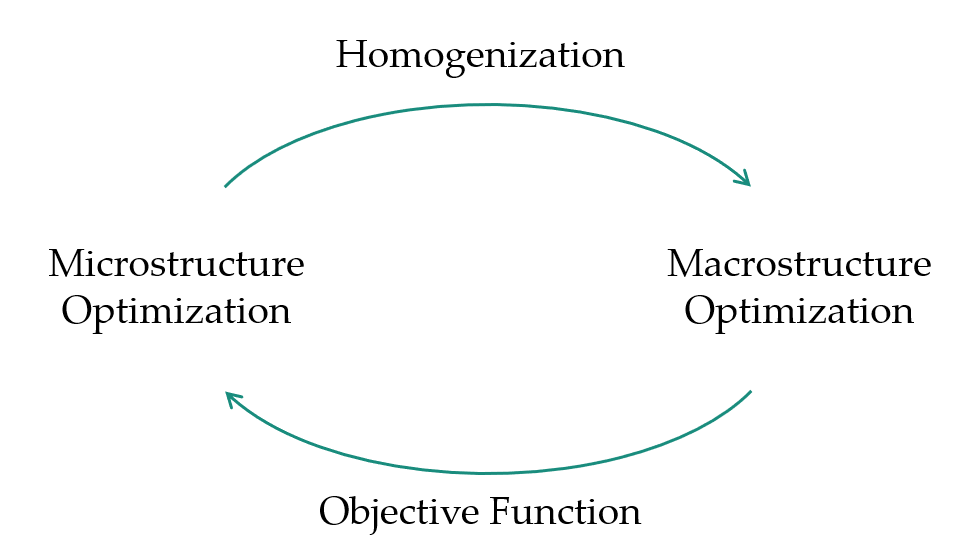

Inverse Design Process

Microstructure Optimization

Compliant Mechanism Design of Trusses

\[ \begin{aligned} & \underset{\rho^e}{\text{minimize}} & & V(\rho^e)=\sum_{e \in \Omega } \rho^e \upsilon^e \\ & \text{subject to} & & K (\rho^e)d-F=0 \\ & & & g= L_i^T d\leq d_{max,i} \ \forall i \in 1,..,m \\ & & & \rho^e_{min} \leq \rho^e \ \forall e \\ & \end{aligned} \]

Using the adjoint method

The gradient of objective function: \[ f= \sum_{e \in \Omega } \rho^e \upsilon^e \\ \frac{\delta f}{\delta \rho_e}=\sum_{e \in \Omega } \upsilon^e \] The gradient of each constraint $i \ \forall (1,..,m)$: \[ \frac{\delta g_A}{\delta \rho_e}= - \lambda_i^T \frac{\delta K(\rho_e)}{\delta \rho_e } d \\ \]

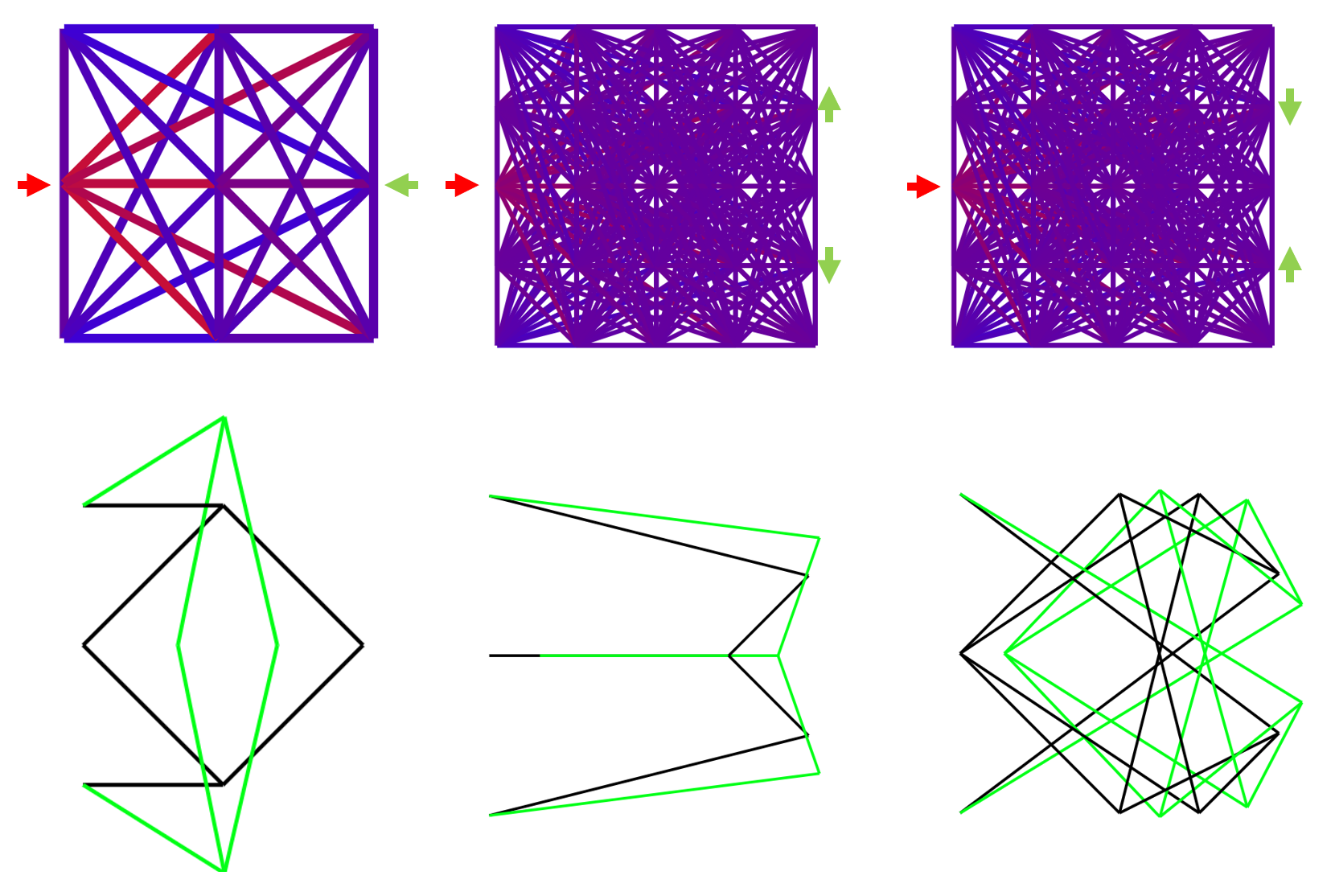

2D Initial Results

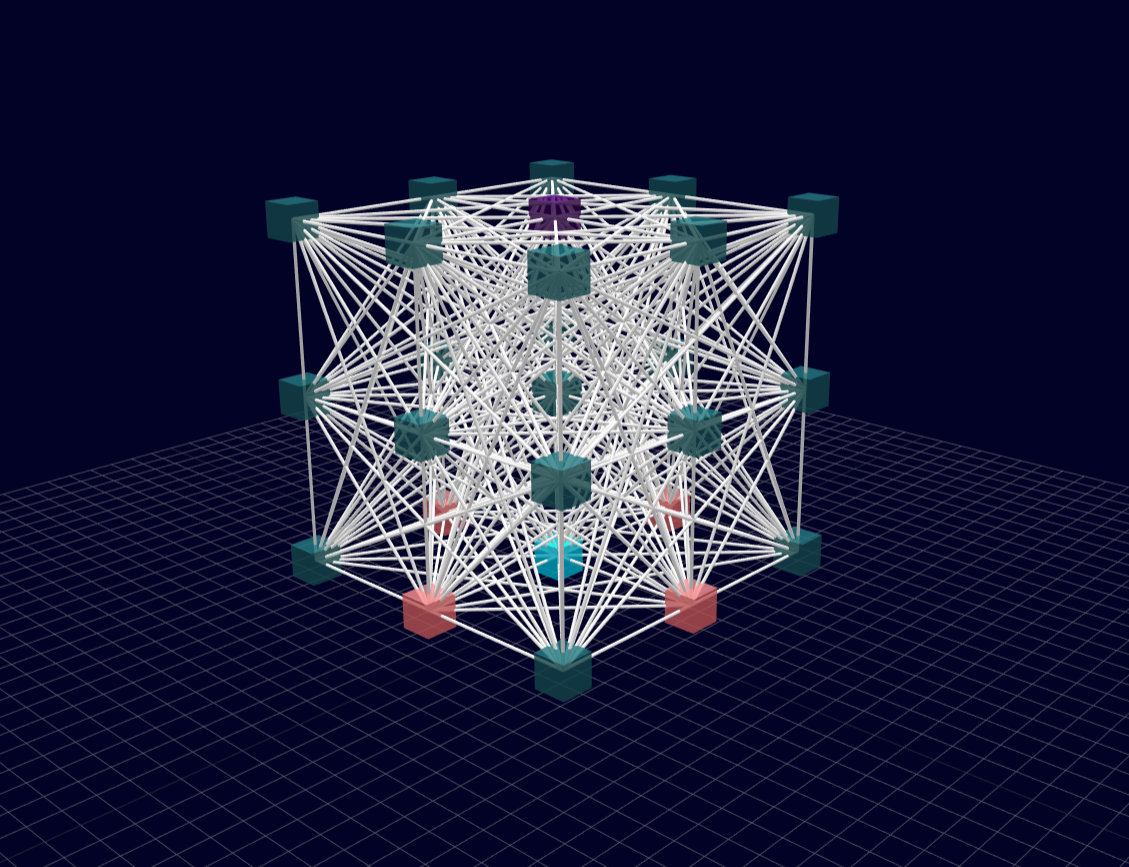

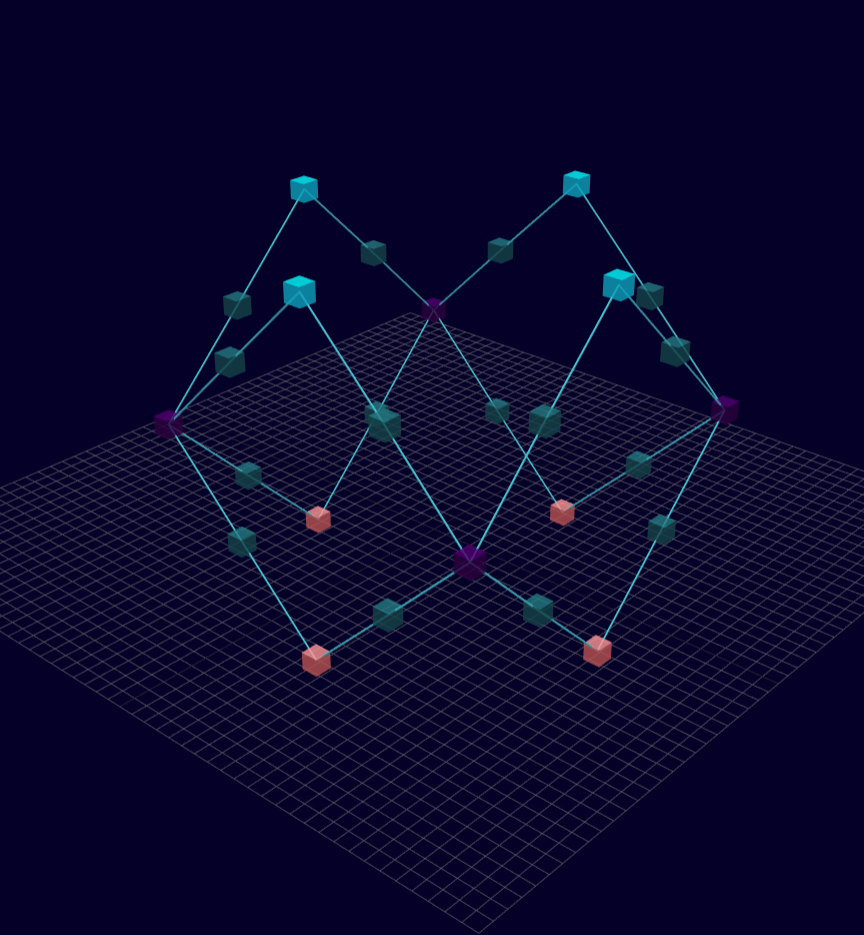

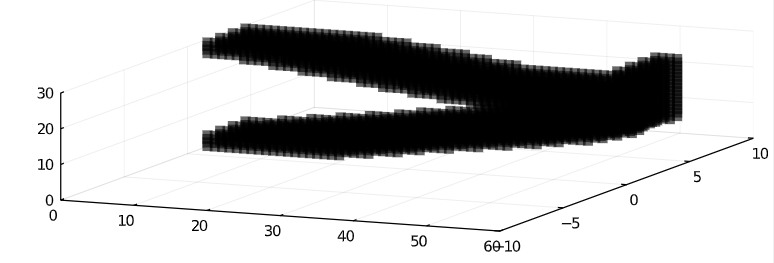

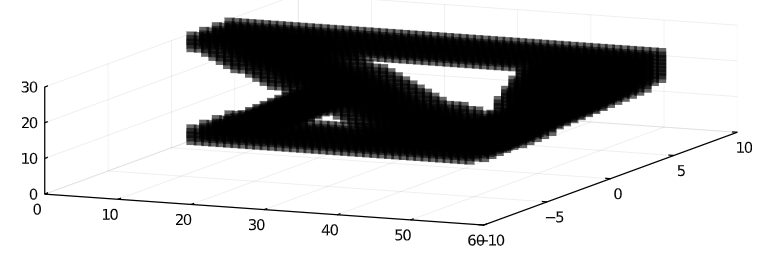

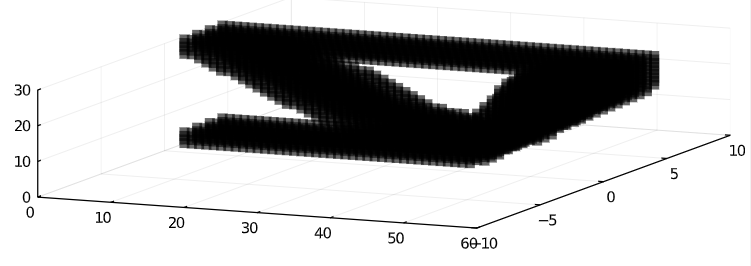

3D Initial Compliant Mechanisms Results

Results: Microstructures after Manual Cleanup

Homogenization

\[ {\mathbf{C}}^H=\frac{1}{\left|{\Omega}_m\right|}{\int}_{\Omega_m}\mathbf{C}\left(\varepsilon \left({\mathbf{u}}_m^0\right)-\varepsilon \left({\mathbf{u}}_m\right)\right)\left(\varepsilon \left({\mathbf{u}}_{\mathrm{m}}^0\right)-\varepsilon \left({\mathbf{u}}_m\right)\right)\mathrm{d}{\Omega}_m \] \[ {\int}_{\Omega_m}\mathbf{C}\varepsilon \left({\mathbf{u}}_{\boldsymbol{m}}\right)\varepsilon \left({\boldsymbol{\nu}}_m\right)\mathrm{d}{\Omega}_m={\int}_{\Omega_m}\mathbf{C}\varepsilon \left({\mathbf{u}}_m^0\right)\varepsilon \left({\boldsymbol{\nu}}_m\right)\mathrm{d}{\Omega}_m,\kern1.25em \forall {\boldsymbol{\nu}}_m\mathbf{\in}{H}_{per}\left({\Omega}_m,{\mathbb{R}}^d\right) \]

Homogenization Results

Youngs Modulus

| Lattice | E11 | E22 | E33 |

|---|---|---|---|

| Cube | 6.9e7 | 6.9e7 | 6.9e7 |

| Cuboct | 9.85e7 | 9.85e7 | 9.85e7 |

| Auxetic | 2.584e8 | 1.608e8 | 1.608e8 |

| Chiral | 1.12e8 | 1.14e8 | 1.14e8 |

Shear Modulus

| Lattice | G23 | G31 | G12 |

|---|---|---|---|

| Cube | 1.45e6 | 1.45e6 | 1.45e6 |

| Cuboct | 5.04e7 | 5.04e7 | 5.04e7 |

| Auxetic | 3.34e7 | 6.78e7 | 3.34e7 |

| Chiral | 5.45e7 | 6.4e7 | 5.45e7 |

Poisson Ratio

| Lattice | v12 | v13 | v23 | v21 | v31 | v32 |

|---|---|---|---|---|---|---|

| Cube | 0.056 | 0.056 | 0.056 | 0.056 | 0.056 | 0.056 |

| Cuboct | 0.294 | 0.294 | 0.294 | 0.294 | 0.294 | 0.294 |

| Auxetic | 0.063 | 0.063 | 0.376 | 0.039 | 0.039 | 0.376 |

| Chiral | 0.2 | 0.2 | 0.43 | 0.21 | 0.21 | 0.43 |

Macrostructure Optimization

Multi-Material Topology Optimization

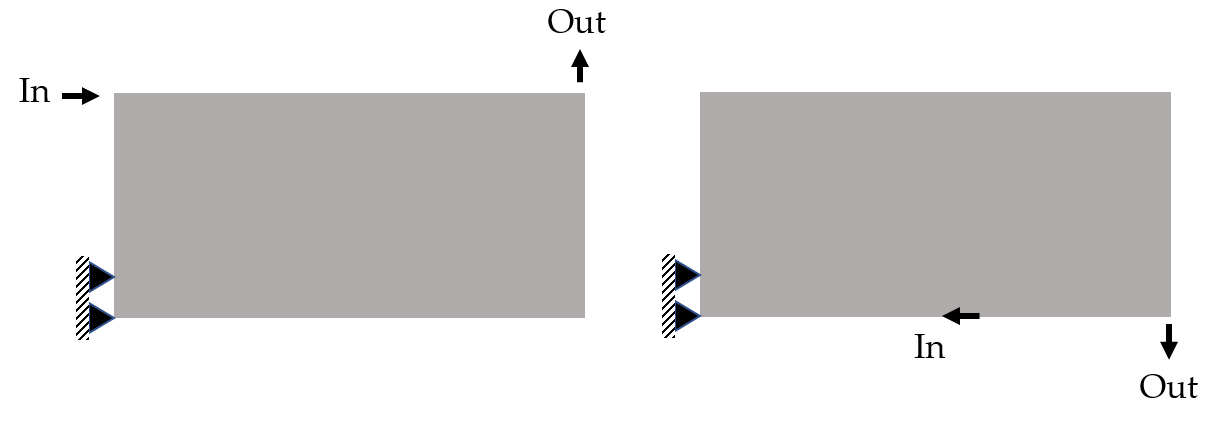

The materials distribution is determined by the local volume fraction fields, α i (i = 1, … , p) \[ \boldsymbol{A}^{h} := \left\{ \alpha^{h} \in \left\{\alpha_{i}^{h} \in \boldsymbol{V}^{h}\left(\Omega^{h}\right)\right\}_{i\in \{1, \ldots, p\}} \left| \begin{array}{l} \\\\\\ \end{array} \right.\right. \] \[ \left. \begin{array}{ll} \sum_{i=1_{}}^{p} \alpha_{i}^{h} = 1, & \\ \int_{\Omega^{h}_{}} \alpha_{i}^{h} \ dx = \Lambda_{i} |\Omega^h|,\quad & i=1, \ldots, p \\ \boldsymbol{l}_{i}^{h} \leqslant \alpha_{i}^{h} \leqslant \boldsymbol{u}_{i}^{h}, \quad & i=1, \ldots, p \end{array} \right\} \]Implementation Results: MBB and Gripper

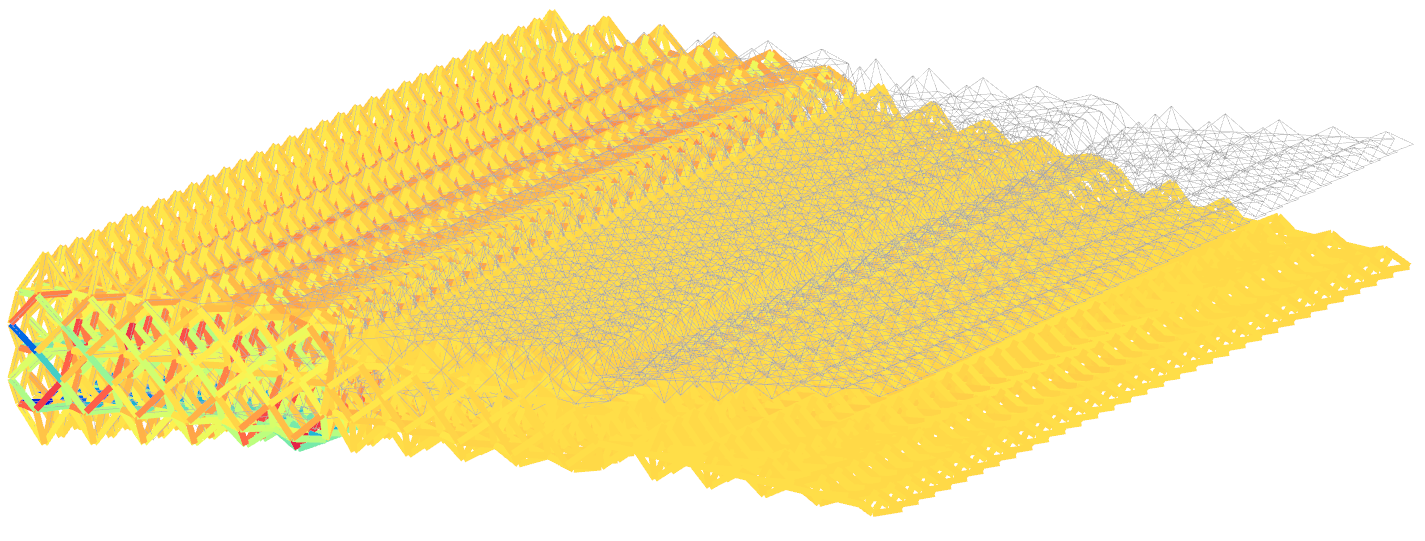

Extended code to 3D and implemented compliance objective

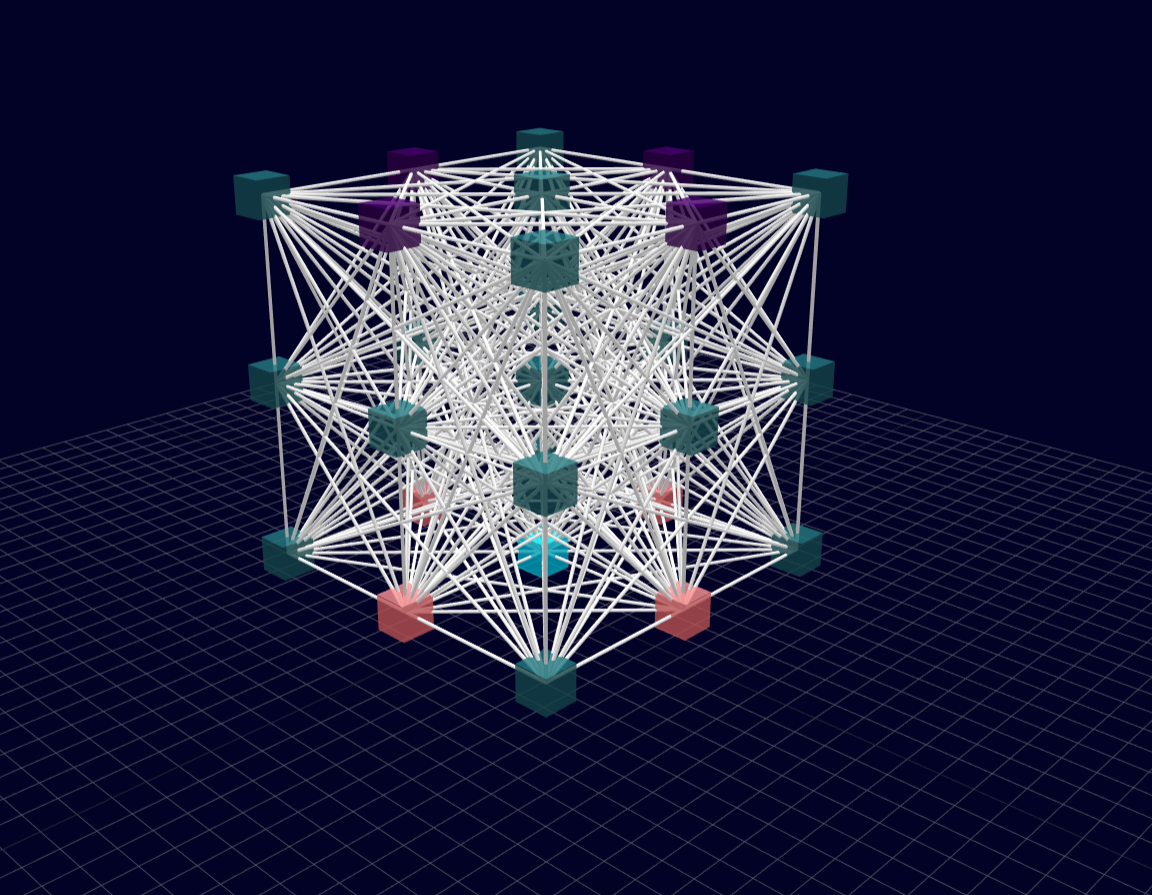

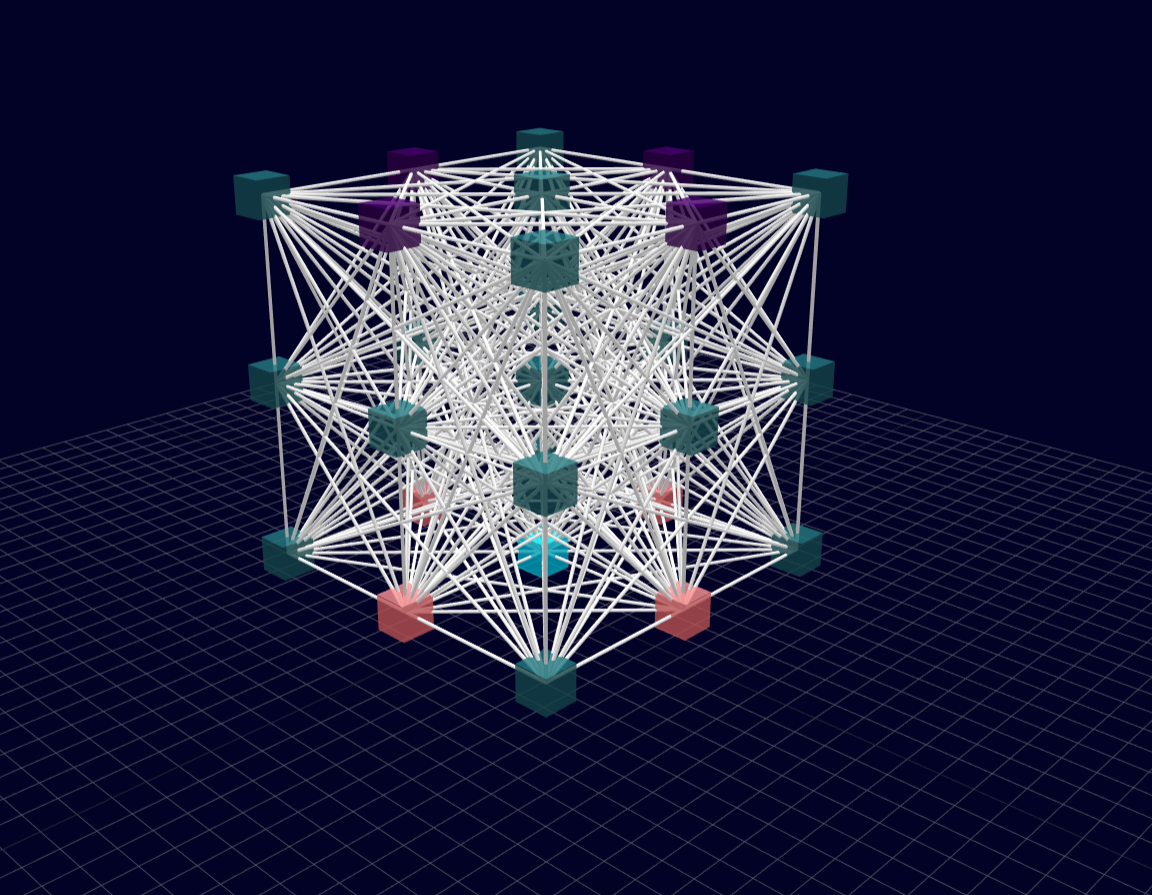

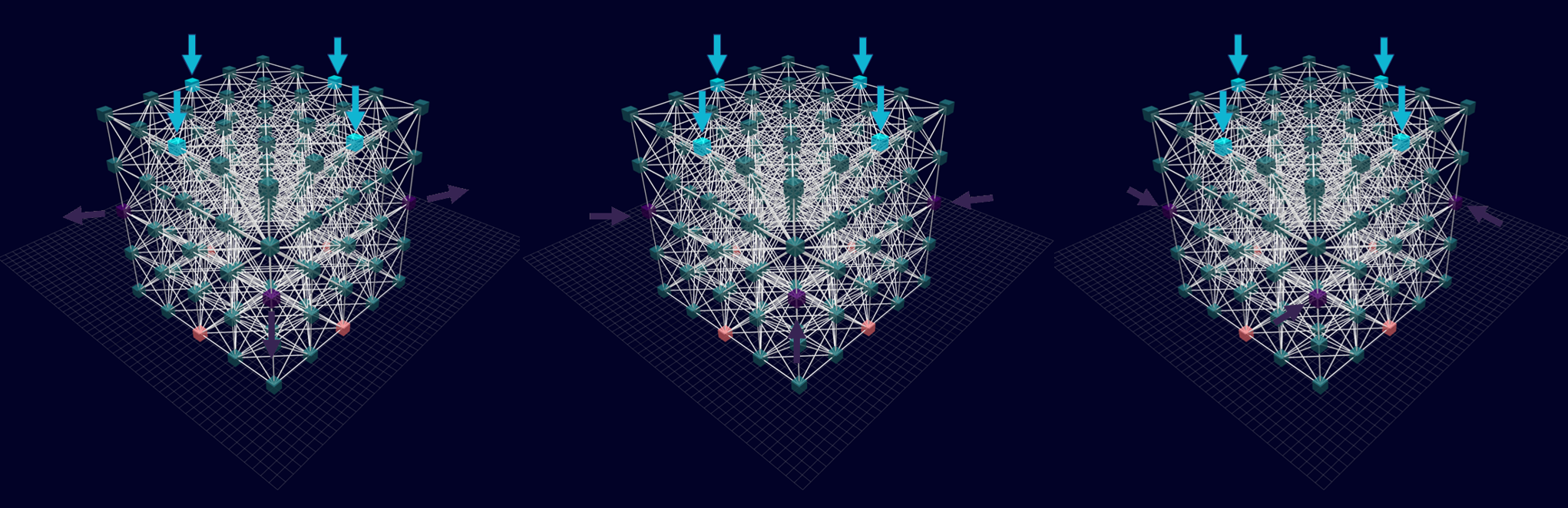

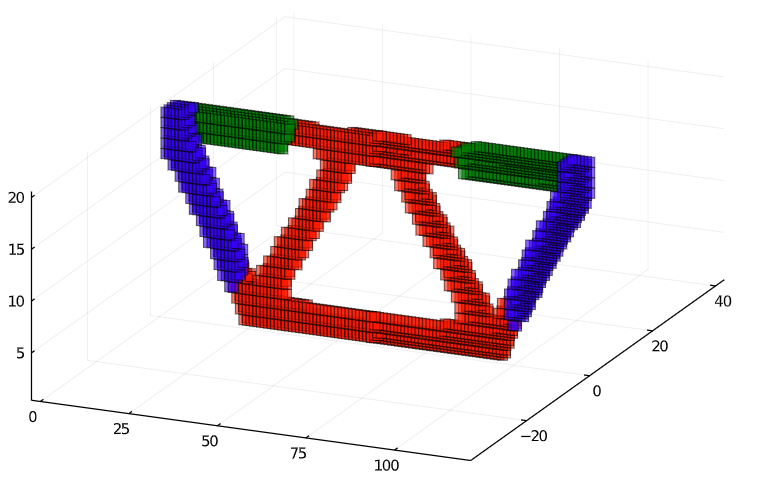

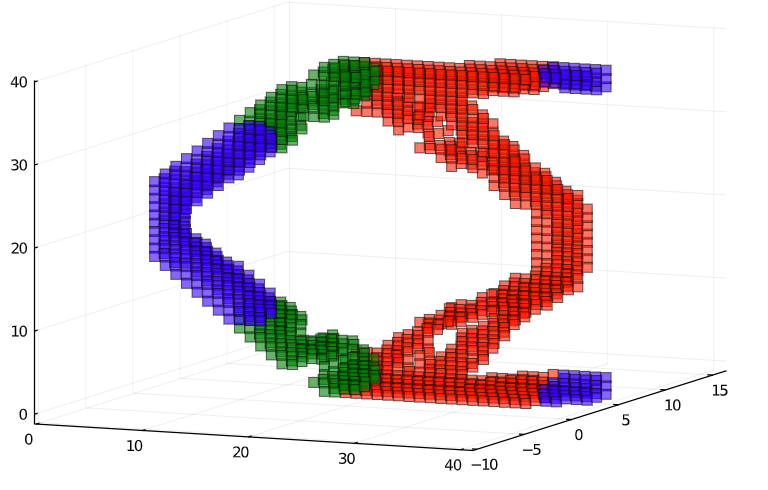

Hierarchal Topology Optimization

Cube Cuboct

Auxetic Chiral

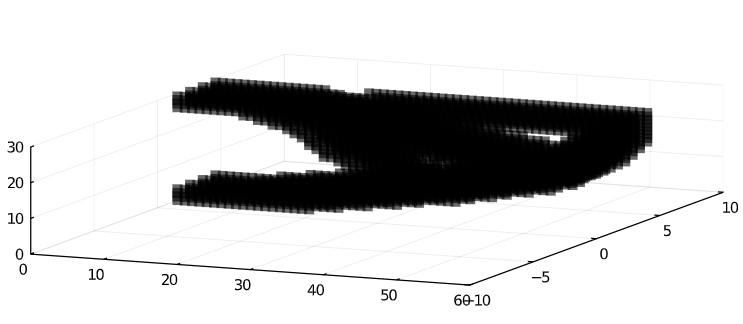

Morphing Wing Problem Formulation

Final Results (Using same cuboct with different densities)

Red more stiff then blue then red.